First: a little backstory. When I got a book deal (book deal!

First: a little backstory. When I got a book deal (book deal! ), I decided that I really wanted to do something nice for myself. But what? And so, after some soul searching, I decided exactly what I wanted to do.

), I decided that I really wanted to do something nice for myself. But what? And so, after some soul searching, I decided exactly what I wanted to do.

1. I wanted some hot chocolate.

2. I wanted some new legwarmers.

3. I wanted to tour a butter factory.

Well, goal 1 was easily realized, at a sweet little spot that you might know as 7-11 (my guilty pleasure!). Goal 2 was realized by way of some delightful over-the-knee legsweaters obtained at Buffalo Exchange in Portland (they are perfect. If you've been to my store or seen me in the past few months, you have most likely seen me wearing them). And finally, this week, thanks to my friend Colin, who has family butter connections (I know! I am jealous too), I got to tour a butter factory--the Darigold plant in Issaquah. But really, you should know that I would never take on something as epic as a butter factory tour without doing my homework.

First, I educated myself on the various types of butter.

First, I educated myself on the various types of butter.

Then, I learned a bit more about sweet cream (uncultured) butter, which is the primary sort you'll buy by the stick in the US (and the type made by Darigold). But what is this type of butter, exactly? Per the Darigold site,

Today’s creameries use highly controlled production methods. First, fresh, sweet milk is inspected for quality, milkfat content and weight. The cream is then separated and prepared for pasteurization. To pasteurize the cream, it’s heated to at least 161°F for 15 seconds. Ultra-pasteurized milk and ultra-high temperature processed milk are heated to 280°F for at least two seconds. The extreme heat reduces levels of bacteria that can cause cream to spoil and, in turn, increases the refrigerated shelf life of butter.

Once pasteurization is complete, the cream is churned until it becomes solid. The butter is then packaged and ready for distribution to your local supermarket.

Interesting: the method of creating butter in the USA is not the same as creating butter in other parts of the world. Butterfat, in particular, affects texture and taste.

Interesting: the method of creating butter in the USA is not the same as creating butter in other parts of the world. Butterfat, in particular, affects texture and taste.

The amount of butterfat in the finished product is a vital aspect of production. In the United States, products sold as "butter" are required to contain a minimum of 80% butterfat; in practice most American butters contain only slightly more than that, averaging around 81% butterfat. European butters generally have a higher ratio, which may extend up to 85%.

And, in case you were wondering, this is also, like, why the pastries in Paris have a certain je ne sais quoi.

But on to the factory itself.

But on to the factory itself.

When we got there, I was told to take off all my jewelry and to put on this totally sweet getup. Colin, who took the photo, was wearing it too. Neither of us had to wear a beard net, although we could have if we wanted to.

When we got there, I was told to take off all my jewelry and to put on this totally sweet getup. Colin, who took the photo, was wearing it too. Neither of us had to wear a beard net, although we could have if we wanted to.

And then Bret, who is a consultant at Darigold, gave us the grand tour. How is butter made, you wonder? Well. Darigold gave me the 411:

Today’s creameries use highly controlled production methods. First, fresh, sweet milk is inspected for quality, milkfat content and weight. The cream is then separated and prepared for pasteurization. To pasteurize the cream, it’s heated to at least 161°F for 15 seconds. Ultra-pasteurized milk and ultra-high temperature processed milk are heated to 280°F for at least two seconds. The extreme heat reduces levels of bacteria that can cause cream to spoil and, in turn, increases the refrigerated shelf life of butter.

Today’s creameries use highly controlled production methods. First, fresh, sweet milk is inspected for quality, milkfat content and weight. The cream is then separated and prepared for pasteurization. To pasteurize the cream, it’s heated to at least 161°F for 15 seconds. Ultra-pasteurized milk and ultra-high temperature processed milk are heated to 280°F for at least two seconds. The extreme heat reduces levels of bacteria that can cause cream to spoil and, in turn, increases the refrigerated shelf life of butter.

Once pasteurization is complete, the cream is churned until it becomes solid. The butter is then packaged and ready for distribution to your local supermarket.

Of course, what I got to see at the factory were the tubes and silos through which the separated cream is run and turned into butter, the big (biggest in the US!) French butter churning machine, and the packaging machines which dole the butter out into packs -- most commonly quarter-pound packages, but they also do jumbo "chef's style" blocks too.

We also got to meet Jeff, who tests the butter to ensure that it meets the regulations for butterfat and moisture content.

Hi, Jeff!

When I pressed him to see if he really thought that spring butter was the best (it is said that the cows that feed on the green spring grass really do yield the best milk) he said that though there was a difference, it was small. But when he showed me his diary -- er, log--of the butterfat content on a daily basis, it did look like the percentages were higher (and more delicious?) in the spring versus winter, when cows are eating dry grass. It should be noted that while some dairies will employ annatto to color their butter to ensure that it looks the same year-round, Darigold only adds cream and salt to theirs, so natural color variations may occur. This is a good thing, people--it's nature's way.

When I pressed him to see if he really thought that spring butter was the best (it is said that the cows that feed on the green spring grass really do yield the best milk) he said that though there was a difference, it was small. But when he showed me his diary -- er, log--of the butterfat content on a daily basis, it did look like the percentages were higher (and more delicious?) in the spring versus winter, when cows are eating dry grass. It should be noted that while some dairies will employ annatto to color their butter to ensure that it looks the same year-round, Darigold only adds cream and salt to theirs, so natural color variations may occur. This is a good thing, people--it's nature's way.

Jeff, as it turns out (my new bff!) is also a doughnut enthusiast. We share a passion for Chuck's Donuts in Renton, and he tipped me off on a new place (to me) called Legendary Donuts. Yes, I liked Jeff.

Oh, and while we were there, an artist was at work doing a mural of a starship attacking bacteria--a little acidopholus humor for you!

Oh, and while we were there, an artist was at work doing a mural of a starship attacking bacteria--a little acidopholus humor for you!

By the way, the same artist doing said mural had also done one outside of the plant which illustrates Darigold's storied history in the Northwest (they have been around since 1918!)

By the way, the same artist doing said mural had also done one outside of the plant which illustrates Darigold's storied history in the Northwest (they have been around since 1918!)

We also got to see cottage cheese being made (an oddly hypnotic process), as well as seeing various dairy products being packaged, palletized, and put on the loading dock, where they will make their way to various accounts all around the northwest. Unlike many industries during this down economy time, Darigold continues to grow--perhaps owing to the return to home arts, and sharing memories over baking? I like to think this way.

But this wasn't all--once done here, we went back to Seattle and visited the corporate offices of Darigold. I will do another post to tell you all about that, ok?

For more information about Darigold, visit their official site. To learn more about different types of butter, here's a great post on Saveur.

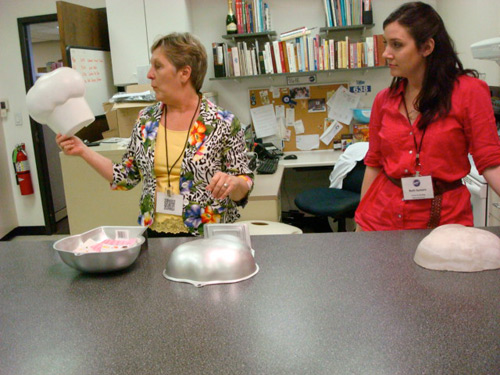

Of course you've heard of Wilton. They make, like, everything that you could ever dream of to decorate cakes with: pans, equipment, sprinkles, decorations, fondant and decorating icing, and so much more. And recently, myself and about 20 other awesome movers-and-bakers were invited for a day of buttercream bliss at their facilities in the Chicago area. Here, let me tell you all about my day.

Of course you've heard of Wilton. They make, like, everything that you could ever dream of to decorate cakes with: pans, equipment, sprinkles, decorations, fondant and decorating icing, and so much more. And recently, myself and about 20 other awesome movers-and-bakers were invited for a day of buttercream bliss at their facilities in the Chicago area. Here, let me tell you all about my day.

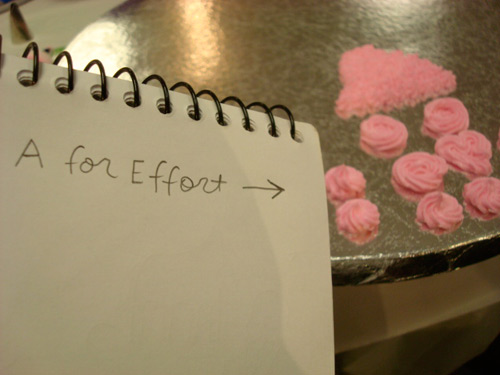

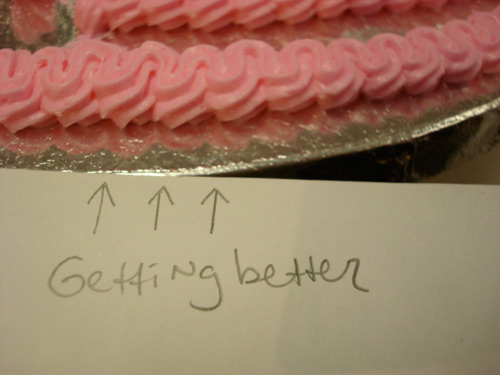

...and of course, this:

...and of course, this:

oh, and did I mention they had snacks? They had cupcakes...

oh, and did I mention they had snacks? They had cupcakes...